Die cutting system

Ps-sf01 Siemens single axis servo registration system is mainly used in automatic die-cutting control, high-end laminating machine automatic color matching control, plate automatic cutting control and other high-precision occasions.

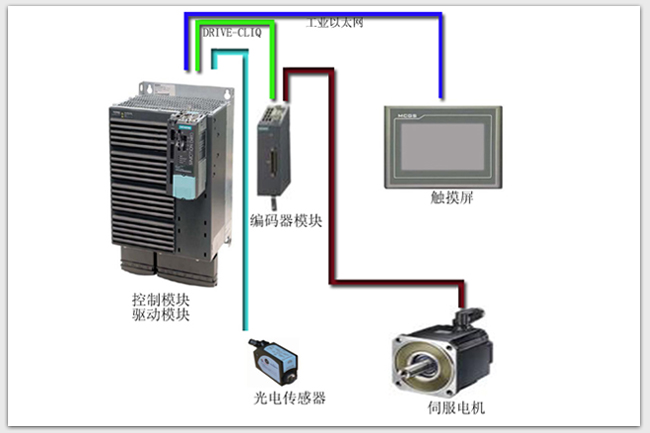

to configure:

Motion control module (Siemens) x 1

Servo drive module (Siemens) x 1

Encoder module (Siemens) x 1

Servo motor (Firth) x 1

Planetary reducer (APEX) x 1

Touch screen (Kunlun state) x 1

Color code sensor (DEX) x 1

Encoder (RIP) x 1

Cable (PSY) x 5

Parameters:

Plate tooth range: 80-250 teeth

Maximum deviation correction range: ± 50mm

Die cutting speed: 250m / min

Die cutting accuracy: ± 0.1mm

characteristic:

(1) Based on Siemens high performance SIMOTION series motion controller design, excellent performance, reliable operation, easy maintenance. Full automatic control, no need for human intervention, and

In order to improve the overall performance of the die-cutting machine.

(2) The mechanical structure is simple. Electronic shaft synchronization technology is adopted, without the need of traditional gearbox transmission mechanism

(3) High die cutting accuracy. The servo system has built-in ultra-high performance encoder, which fully guarantees the system has extremely fast correction speed and ultra-high die cutting accuracy

(4) Easy to operate. Select high-resolution touch screen, fool operation in the whole process, fast hands-on staff, greatly reducing the training cost of customers

(5) Pre registration function. Servo based pre registration has the characteristics of short response time and high precision, which greatly reduces the generation of waste materials